After 20 successful years in the clinker cooler business as a technologically leading company, WEBBER INTERNATIONAL is a reliable partner for conversions and modifications.

We offer a complete range of services, from the replacement of individual plant components, the replacement of only the core parts, to the complete replacement of coolers.

In close coordination and cooperation with our customers, we develop the best possible solution for the respective application.

A Cooler Modification With Or Without A Capacity Upgrade Will Include Design Upgrades With The Focus Will Be On Three Targets:

Finding the right strategy for a cooler upgrade implies that all effects in between the different pyro process steps need to be taken into consideration.

If you plan to upgrade the clinker capacity of the pyro line or want to evaluate a system upgrade of the cooler by a Waste Heat Recovery system, WEBBER INTERNATIONAL is your partner with a precise understanding how these changes impact the interfaces for the overall process.

Through close partnerships in the market WEBBER INTERNATIONAL can offer you the complete cooler package for the required modifications of your existing cooler including exhaust air or water injection system, kiln hood and sealing as well as the providing a new burner platform etc.

Capacity Increase

Upgrading your clinker production rate often surpasses the capacity limits of the existing clinker cooler and it is needed to adapt or even replace the existing system.

Separate cooler components or even the new Aerofoil Cooler are available to be embedded in your plant environment. The use of the latest technologies – if required – like i.e. 3D-Laser Scan technology, WEBBER INTERNATIONAL ensures smooth project execution and a short installation time.

Static Inlet

WEBBER INTERNATIONAL has supplied all its coolers for years with a static grate in the inlet zone of the clinker cooler, the so-called Static Inlet.

In this zone, a high-targeted air supply ensures rapid cooling of the clinker, thus ensuring good clinker quality and a high recuperation air temperature. This is the prerequisite for an energy-efficient kiln system and a high use of secondary fuels.

In recent years, the Static Inlet has been developed to achieve a long service life with low-pressure losses, reducing operating costs to a minimum.

The refractory narrowing and the air cannons in the side area of the Static Inlet ensure an excellent distribution of the clinker on the following grate and the best possible reduction of snowman formation.

A WEBBER INTERNATIONAL Static Inlet can be retrofitted at the Kiln Drop Zone

It can be added to all types of existing coolers to:

- Increase the lifetime of grate plates at the inlet area

- Optimize the material distribution at the Cooler inlet

- Increase recuperation air temperature and hence, the efficiency of the clinker cooler.

- The cost-effective low-pressure and modular design very often allow the reuse of existing fans and an installation during yearly maintenance stoppage.

- For snowman prevention, WEBBER INDIA provides a special horseshoe design in combination with field aeration and an automatic air cannon system.

- If you suspect a need for your cooler here, please contact us.

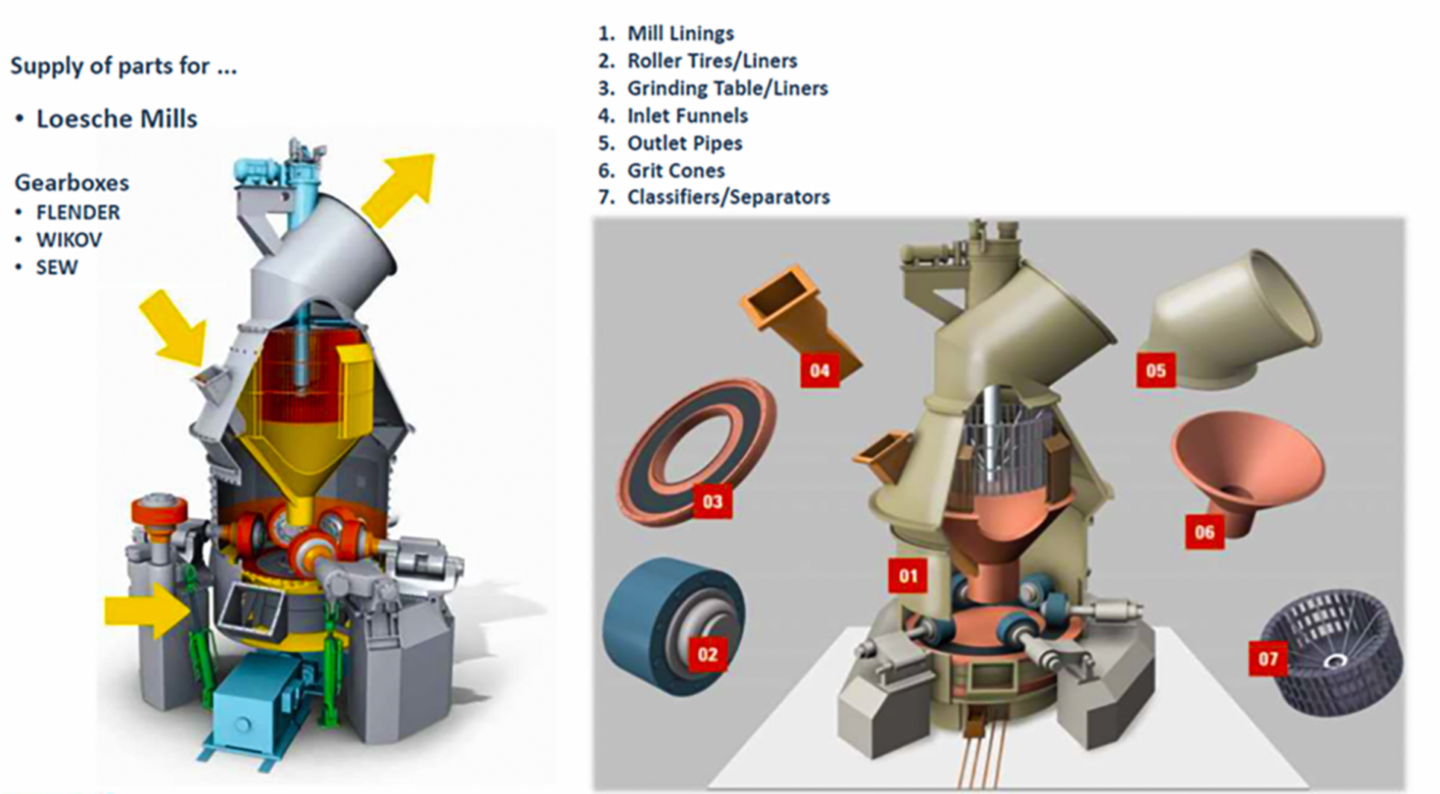

Grinding Category

Raw Mill

Cement Mill

Coal Mill